Call: 08045477907

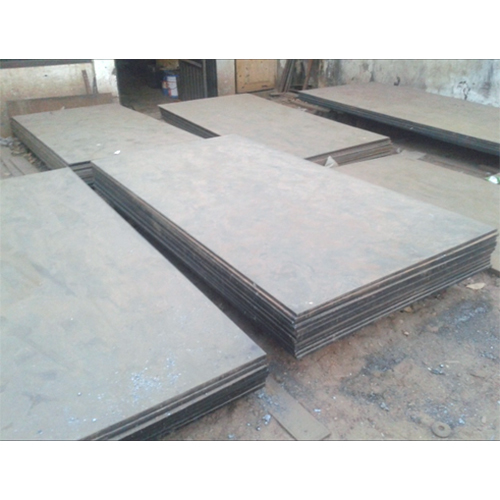

MS Plate

Price 70.0 INR/ Piece

MOQ : 100 Pieces

MS Plate Specification

- Usage

- Structural Applications

- Alloy

- Mild Steel

- Surface Treatment

- Galvanized

- Grade

- IS 2062

- Shape

- Other

- Thickness

- 5mm to 100mm Millimeter (mm)

- Length

- Millimeter (mm)

- Width

- Inch (in)

- Application

- Construction Manufacturing Fabrication

- Color

- Gray

MS Plate Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 2 Days

- Main Domestic Market

- All India

About MS Plate

Product details|

Length |

1250mm to 6300 |

|

Thickness |

All Sizes |

|

Usage/Application |

All Fields |

|

Size (mm X mm) |

Sail,Rinl,Jindal &SECONDARY |

|

Surface Treatment |

Hot Rolled |

|

Width |

1250mm to 2500mm |

|

Material |

MS |

Versatile Structural Solution

Our MS Plates are designed to cater to a broad array of structural applications, owing to their customizable size range and adherence to IS 2062 standards. These plates are particularly valued in the construction and manufacturing industries for their robust structural integrity, making them suitable for buildings, bridges, machinery, and general fabrication tasks.

Tailored for Your Needs

We supply MS Plates with thicknesses from 5mm up to 100mm and offer various customization options in length and width. This flexibility enables architects, engineers, and fabricators to procure exactly what their projects demand, ensuring efficiency and precision during installation.

FAQs of MS Plate:

Q: How can I use MS Plates in construction and fabrication work?

A: MS Plates are ideal for a variety of structural applications such as supporting frameworks, platforms, flooring, brackets, and fabrication of heavy equipment. Their robust properties and adaptability make them a staple material in construction and manufacturing processes.Q: What grade and specifications do these MS Plates comply with?

A: These plates are manufactured from high-quality mild steel, conforming to IS 2062 grade standards. They come in thicknesses ranging from 5mm to 100mm, with customizable length and width options to suit different structural requirements.Q: When should I opt for customized length and width in MS Plates?

A: Opt for customized dimensions when your specific project or machinery demands plates of non-standard sizes. Custom sizing helps reduce wastage, improves fitment, and boosts overall project efficiency.Q: Where are MS Plates commonly used within the construction sector?

A: MS Plates are widely utilized in constructing buildings, bridges, industrial frameworks, shipbuilding, and infrastructure projects. Their strength and versatility make them suitable for load-bearing and structural components.Q: What is the manufacturing process of these MS Plates?

A: Our MS Plates are produced through a combination of hot rolling and precise finishing techniques. High-grade mild steel is processed in mills to achieve the desired thickness, followed by customized cutting to match specified dimensions, ensuring consistency and quality.Q: How does using IS 2062 MS Plates benefit your project?

A: Using IS 2062 compliant MS Plates guarantees high structural strength, reliable weldability, and superior durability. These attributes contribute to safer, more enduring structures, helping you achieve project goals with confidence.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese